Date:2023-01-03

With the continuous improvement of living standards, people's demand for cars is also increasing, which stimulates the continuous development of automobile manufacturing industry. Carbon fiber composite material has the characteristics of light weight, high strength, corrosion resistance and high temperature resistance, and has good environmental protection performance, which plays a very good role in promoting the development of auto parts.

The characteristics of carbon fiber composite material determine its advantageous position in automobile lightweight. This article takes a look at the applications of carbon fiber composites in automotive parts.

1. Automobile body frame

In Europe and America and other developed countries, the application of carbon fiber composite material in the production of body has been very mature, such as McLaren, Ferrari, BMW and so on. Especially in recent years, the application of carbon fiber composite materials in BMW i3 electric vehicles has not only reduced the cost of materials, but also the RTM molding technology developed by the company can improve the efficiency and reduce the cost, which can help it achieve mass production as soon as possible.

2. Car batteries

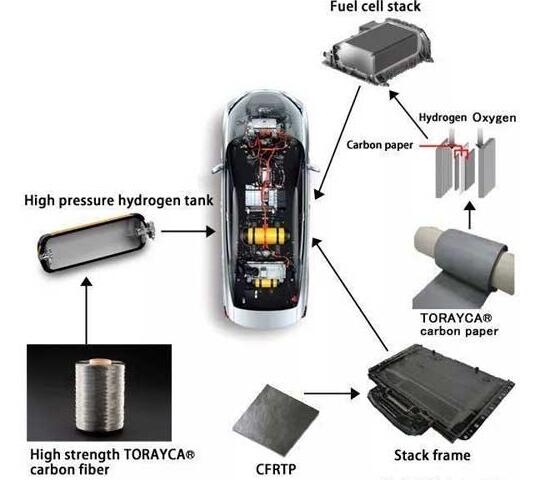

Toray and Toyota jointly developed carbon fiber composites with reinforced thermoplasticity, as well as fuel cell reactor frames, which have been successfully used in battery cars. In addition, the carbon fiber composite material can also be used as the protective shell of the automobile power battery module, which can not only achieve weight reduction, energy saving and emission reduction, but also improve the production efficiency and achieve mass production.

3. Auto body parts

In addition to the above automotive components, the rear rear door, bumper, fender, interior and exterior trim of the car can be made of carbon fiber composite materials. The front bumper can be made of carbon fiber sandwich material to prevent instability and damage. Compared with the bumper made of aluminum alloy extrusion, the weight can be reduced by about 25%. Fender panels are about 39 percent lighter than conventional cold stamping.

With the continuous development of the automobile industry, as well as the gradual improvement of people's environmental awareness, especially under the background of the oil price rise, high-strength and lightweight carbon fiber composite materials will become the mainstream in the future and be rapidly developed, and the corresponding supporting technology will be rapidly improved and improved, the production cost will be gradually reduced, and the efficiency will be significantly improved. Therefore, the application of carbon fiber composites in automobile manufacturing industry will be a trend and has a very broad prospect.